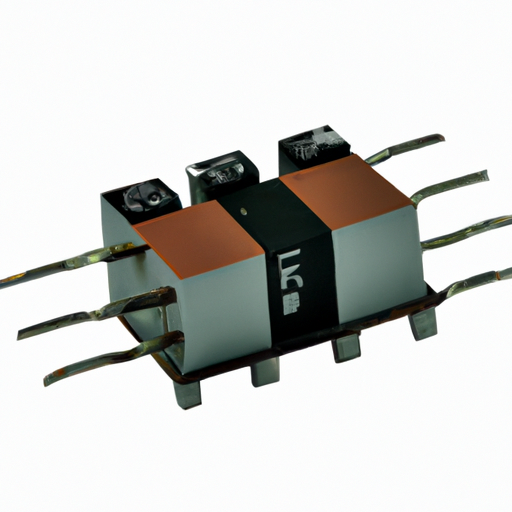

Overview of Isolation Transformers and Autotransformers

Isolation transformers and autotransformers are pivotal components in electrical systems, each serving distinct yet complementary roles in power distribution, voltage regulation, and safety. Below, we delve into the core functional technologies, applications, and notable development cases for both types of transformers, particularly focusing on step-up and step-down configurations.

Core Functional Technologies

Isolation Transformers

1. **Electromagnetic Induction**: Isolation transformers operate on the principle of electromagnetic induction, where the primary and secondary windings are magnetically coupled but electrically isolated. This design prevents direct electrical connection between the input and output.

2. **Voltage Regulation**: They can effectively step up or step down voltage levels while maintaining electrical isolation, which is crucial for protecting sensitive equipment from voltage fluctuations.

3. Noise Reduction: Isolation transformers are adept at filtering out electrical noise and interference, making them ideal for applications involving sensitive electronic equipment, such as audio and video systems.

4. Safety Features: By providing a safety barrier, isolation transformers significantly reduce the risk of electric shock and protect equipment from surges and transients, enhancing overall system reliability.

Autotransformers

1. **Single Winding Design**: Autotransformers utilize a single winding that serves as both the primary and secondary winding. This design allows for a more compact and efficient transformer compared to traditional isolation transformers.

2. Voltage Adjustment: They can step up or step down voltage levels with less copper and core material, resulting in a lighter and more cost-effective solution for voltage regulation.

3. Higher Efficiency: Autotransformers exhibit higher efficiency due to reduced losses in the winding, making them suitable for applications where energy efficiency is paramount.

4. Versatile Applications: Commonly employed in motor starting, voltage regulation, and power distribution, autotransformers are integral to various industrial and commercial applications.

Application Development Cases

Isolation Transformers

1. **Medical Equipment**: Isolation transformers are extensively used in medical devices to ensure patient safety by isolating the device from the mains supply. This is critical in preventing electrical shocks and ensuring the reliability of sensitive diagnostic equipment, such as MRI machines and surgical instruments.

2. Industrial Automation: In industrial settings, isolation transformers protect control circuits and sensitive equipment from voltage spikes and transients, ensuring stable operation of machinery and reducing downtime.

3. Data Centers: Isolation transformers are employed in data centers to provide clean and stable power to servers and networking equipment. This reduces downtime and improves reliability, which is essential for maintaining continuous operations in critical IT environments.

4. Telecommunications: Isolation transformers are used in telecommunications to protect sensitive equipment from surges and to ensure signal integrity, which is vital for maintaining communication quality.

Autotransformers

1. **Motor Control**: Autotransformers are frequently used in motor starting applications where reduced voltage is required to start large motors. This approach minimizes inrush current and mechanical stress on the motor, enhancing its lifespan and performance.

2. Power Distribution: In power distribution systems, autotransformers can efficiently adjust voltage levels, particularly in long-distance transmission where voltage drop is a concern. They help maintain voltage levels within acceptable limits, ensuring reliable power delivery.

3. Renewable Energy Systems: In solar power systems, autotransformers are utilized to match the output voltage of solar inverters to the grid voltage. This facilitates efficient energy transfer and integration of renewable energy sources into the existing power grid.

4. Railway Systems: Autotransformers are commonly used in railway electrification systems to provide the necessary voltage levels for train operation, allowing for efficient energy use and reduced infrastructure costs.

Conclusion

Isolation transformers and autotransformers are essential components in modern electrical systems, each serving unique functions that enhance safety, efficiency, and reliability. Isolation transformers are critical for applications requiring electrical isolation and noise reduction, particularly in sensitive environments like healthcare and data centers. In contrast, autotransformers offer compactness and efficiency for voltage regulation and motor control, making them ideal for industrial and renewable energy applications. As technology continues to advance, the development of these transformers will evolve, leading to more effective and innovative solutions across various industries. The choice between isolation transformers and autotransformers ultimately depends on the specific requirements of the application, including safety, efficiency, and cost considerations.